Larsen supply company presents a 2 minute plumbing video on how to flare copper tubing. The flaring should be even and smooth.

This clip provides an in depth look at the flaring process and addresses proper technique tools and what to look for in a good flare.

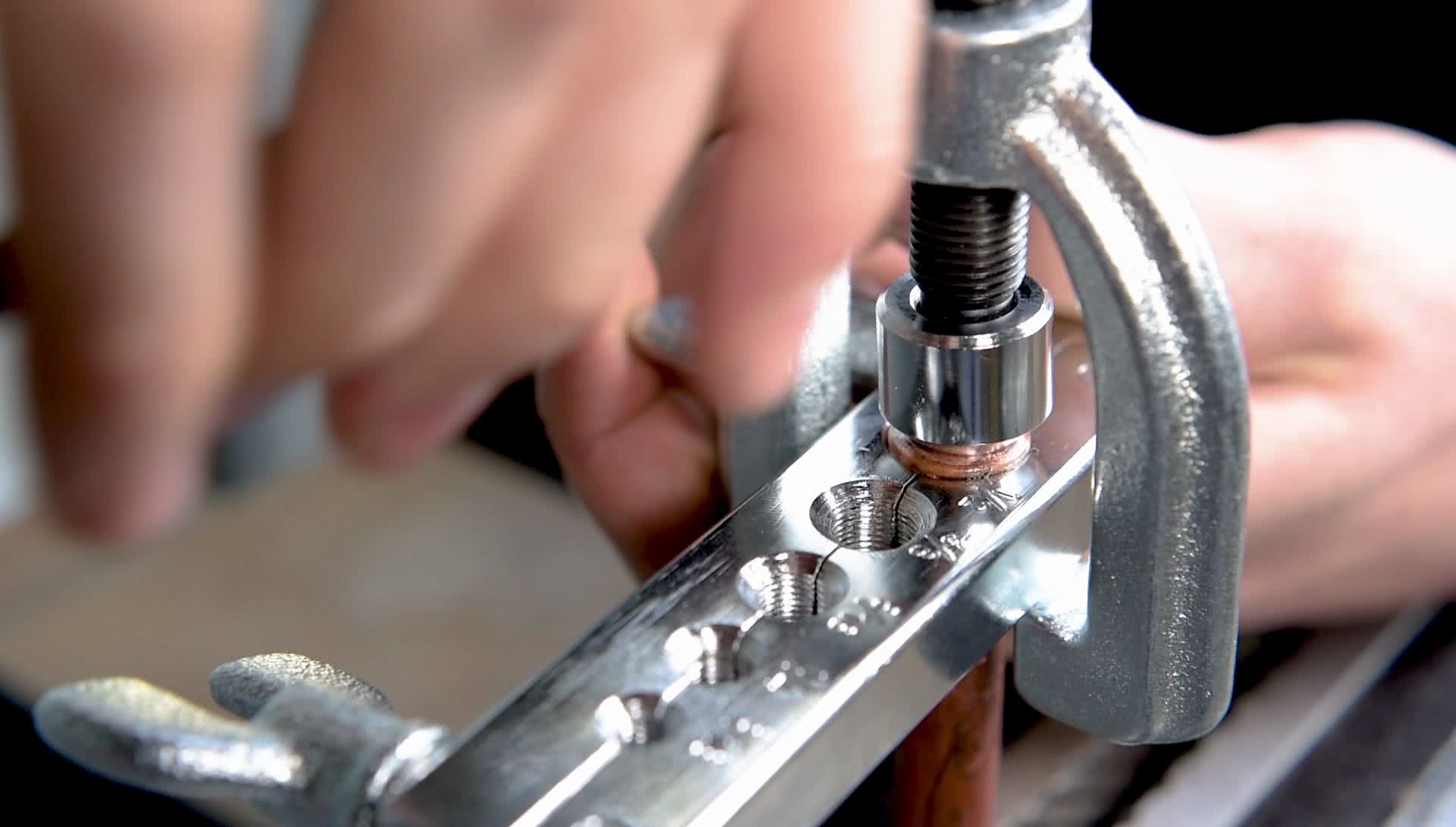

How to use a flaring tool on copper tubing.

To correct this youll need to cut the tubing below the flare and repeat the procedure.

Tutorial on using a copper tube flaring tool.

Loosen the clamps on the flare form and remove the copper tubing.

Place the tubing in the flaring tool.

The flare copper tubing is joined to a special.

Fix it man mark kimball shows how its done.

Cut your copper or aluminum using a tube cutter to ensure a clean cut hacksaws and other cutting tools can make for an uneven cut or burrs which will compromise the flare.

Flare copper tubing for gas using a 2 piece flaring tool that first clamps onto the copper tube then tightens down to create the conical flare.

Theres nothing i hate more than running around to different supply.

However flaring copper water tubing for actual water service lines requires skill.

When flaring begin by choosing the tool accessories that match the diameter of the tube to be flared.

Place the tubing inside the die block or clamp of the flaring tool.

Copper tubing comes in four different types based on its wall thickness.

Use a deburring tool or abrasive cloth to remove any burrs and debris in and around the pipe end.

The end of the tube should extend about 18 inch about the height of a nickel from the flaring tool.

If the flaring isnt even or smooth this is due to the pipe slipping as you used the reamer.

Type k copper water tubing is meant for flaring.

A drip on a a copper line for your ice maker is far different than a drip on your underground main water service line.

Loosen the reamer until you can remove it.

In my business certain jobs require a specific part in order to do the project.

To view the full chapter on the tubing tools dvd go to www.

No comments:

Post a Comment